ABOUT US

Breakthrough

Kunshan BCTM

INTRODUCTION

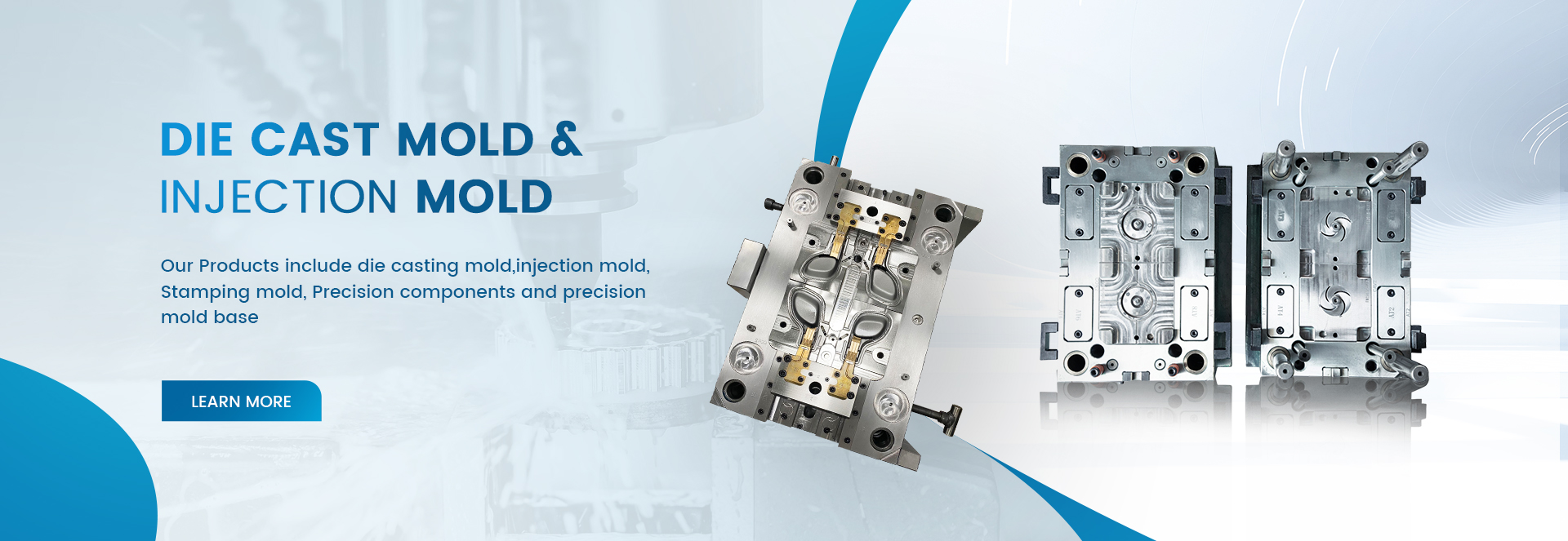

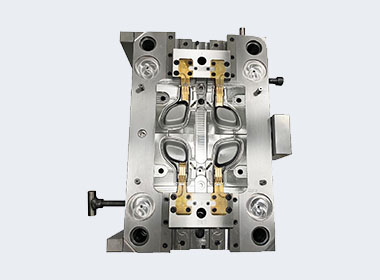

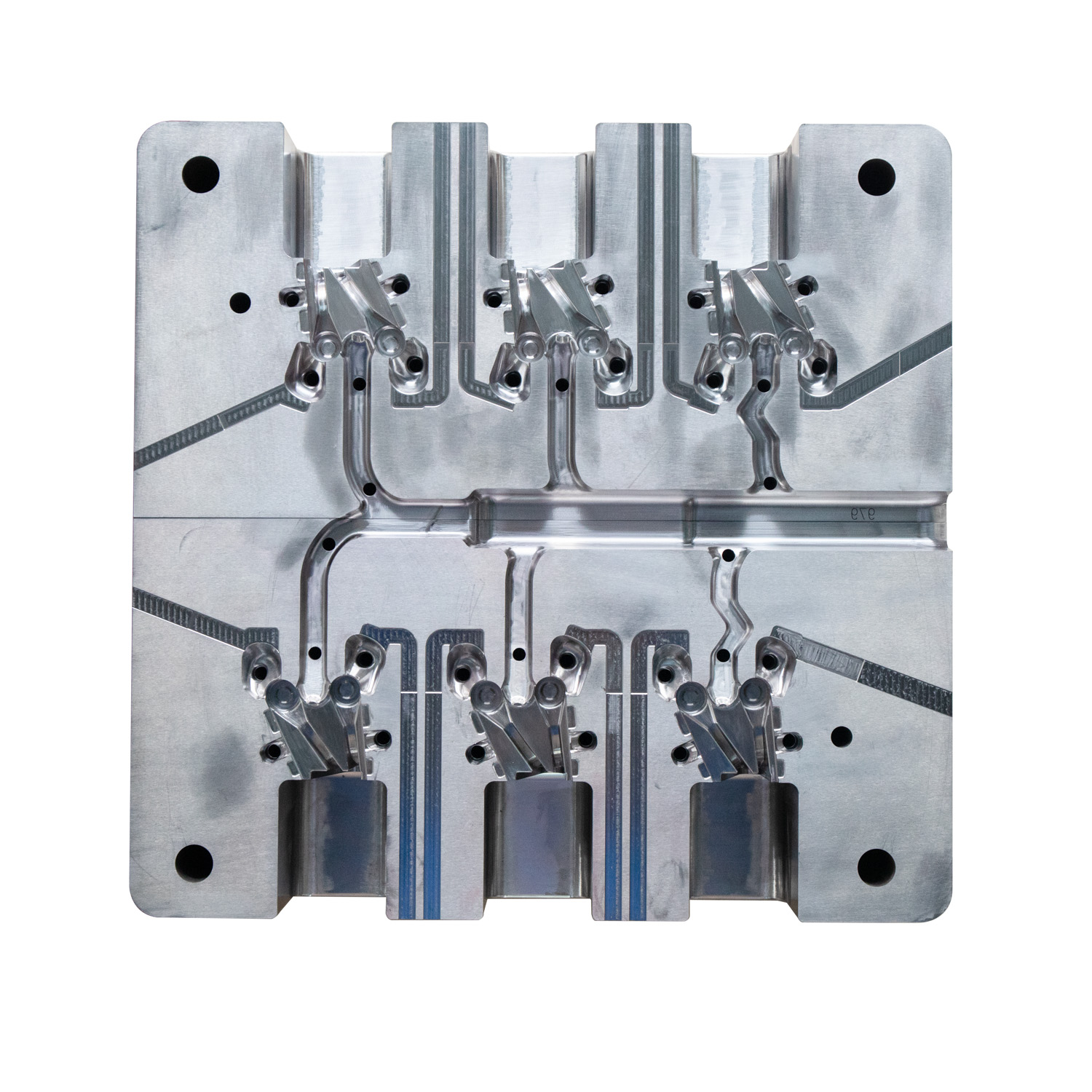

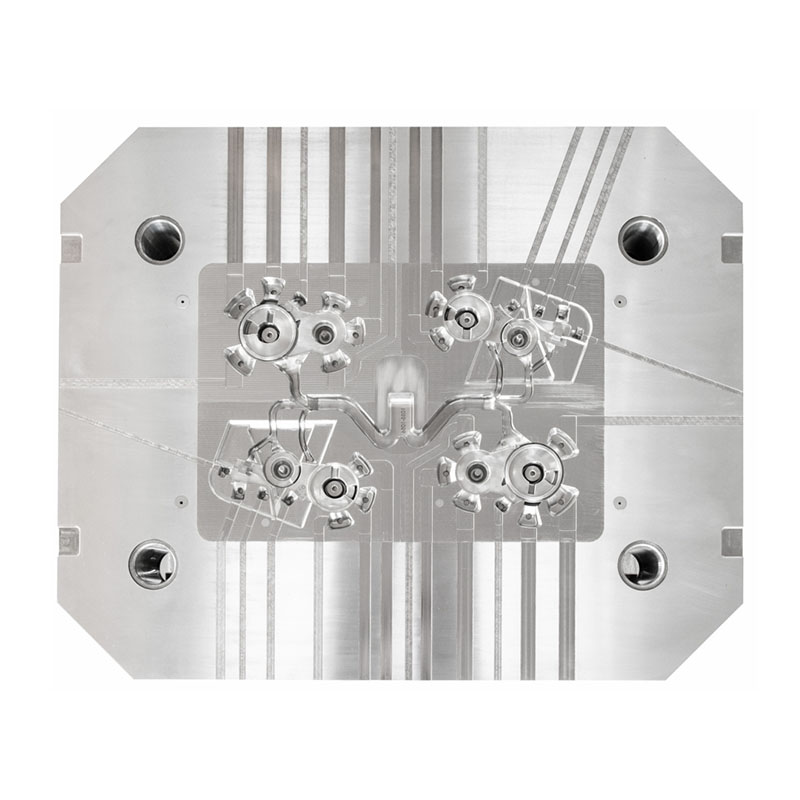

KLAK-Ling is a leading precision mould manufacturing company. We are professionally engaged in the design and manufacture of various types of injection, quality high pressure die-casting, stamping molds, mold components and engineering production, including automatic processing, welding processing, etc. with a highly skilled professional team and advanced processing centers in the field of mould manufacturing in China. We are dedicated to providing a comprehensive one-stop service to our clients. Tailored customization solutions, precision processing, comprehensive after-sales support, and rigorous production tracking. This holistic approach enables us to meet the diverse manufacturing requirements of our clients.

-

-Founded in 2007

-

-16 years experience

-

-+More than 5 products

-

-$More than 7 application fields

products

Innovation

NEWS

Service First

-

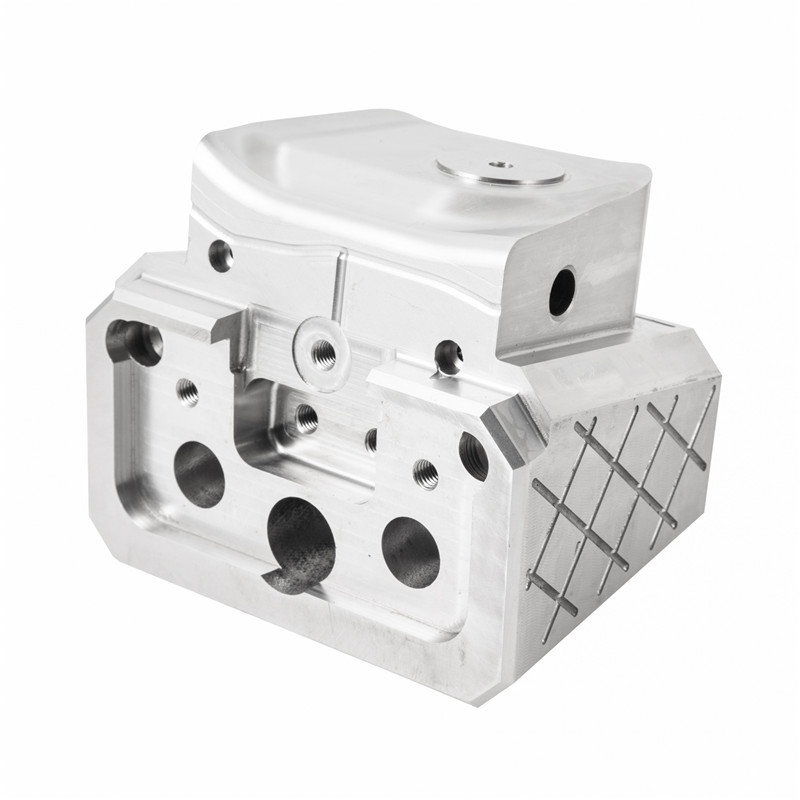

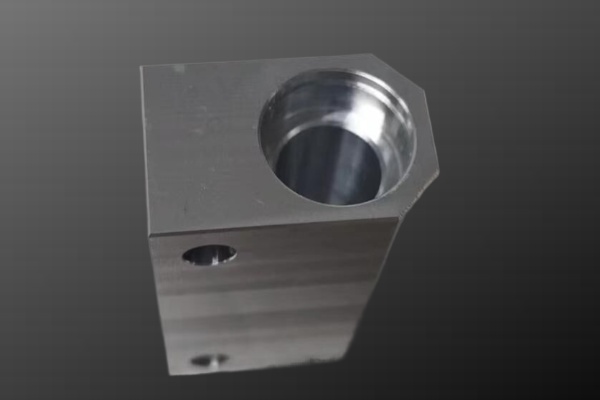

Automated Aluminum Parts

CNC (Computer Numerical Control) aluminum processing technology, with its high precision, high efficiency, and flexibility, has become a crucial pillar of modern manufacturing. Here are some notable features and advantages of CNC aluminum parts processing: ...

-

Welding Parts

Industrial welding is a crucial manufacturing technique that joins metals or other thermoplastic materials together using heat or pressure. This article will i...