Professional Production of Die-Casting Mold Bases

Product Introduction

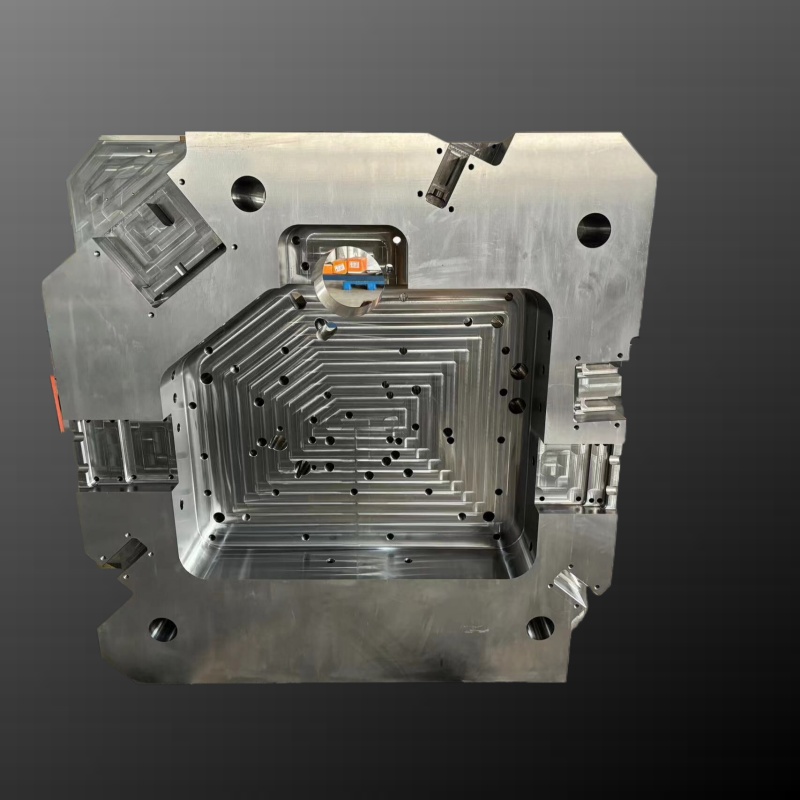

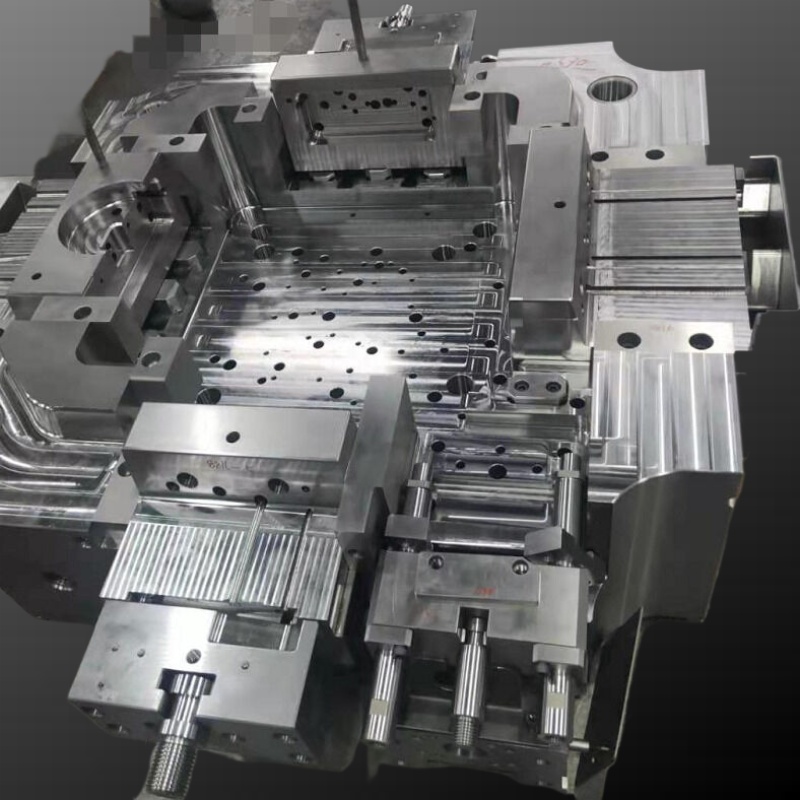

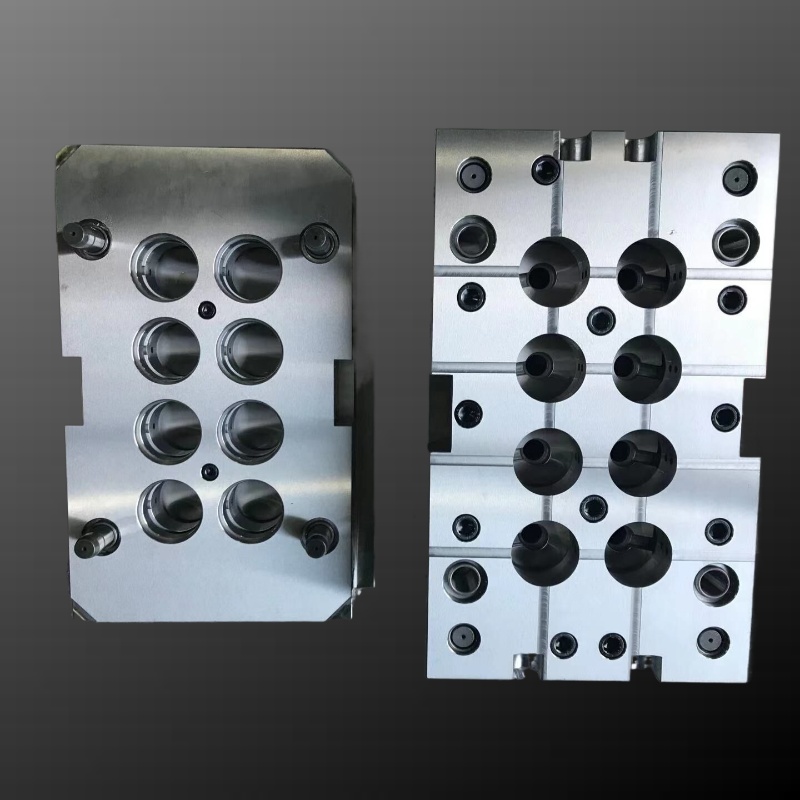

Professional Production of Die-Casting Mold Bases

Our die-casting mold bases employ high-quality alloy materials to ensure stability and durability under high temperatures and pressure. During the production process, we use advanced CNC technology to achieve strict dimensional tolerances and complex geometric shapes through precise machining.

1. Material Selection: We choose high-strength alloy materials to guarantee the longevity and high wear resistance of the mold bases.

2. Design and Process: Our engineering team relies on advanced software for mold base design, ensuring every detail meets customer needs.

3. Quality Control: A rigorous quality inspection process ensures that every product complies with international standards.

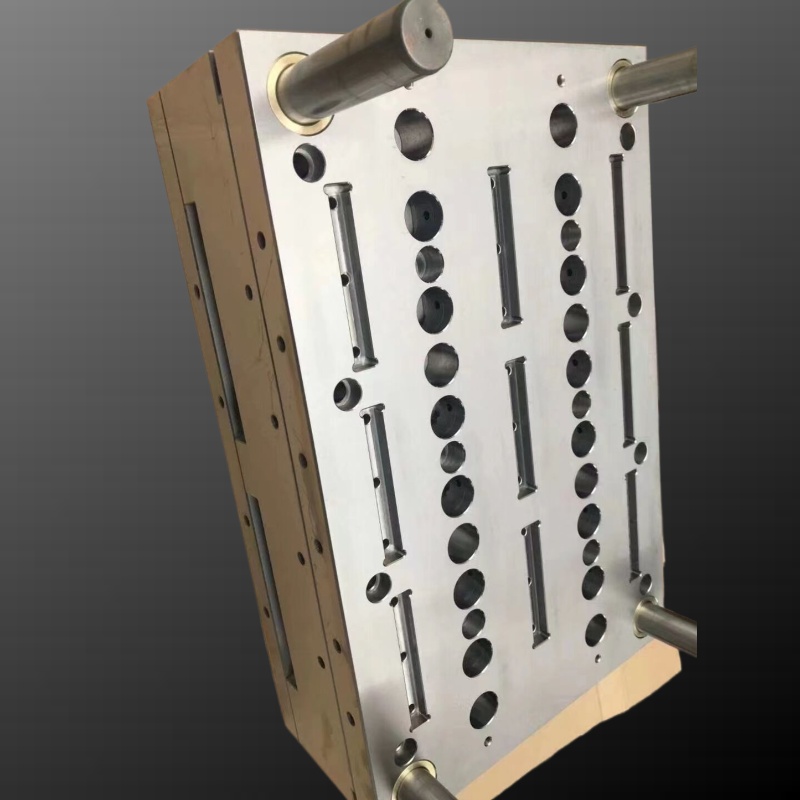

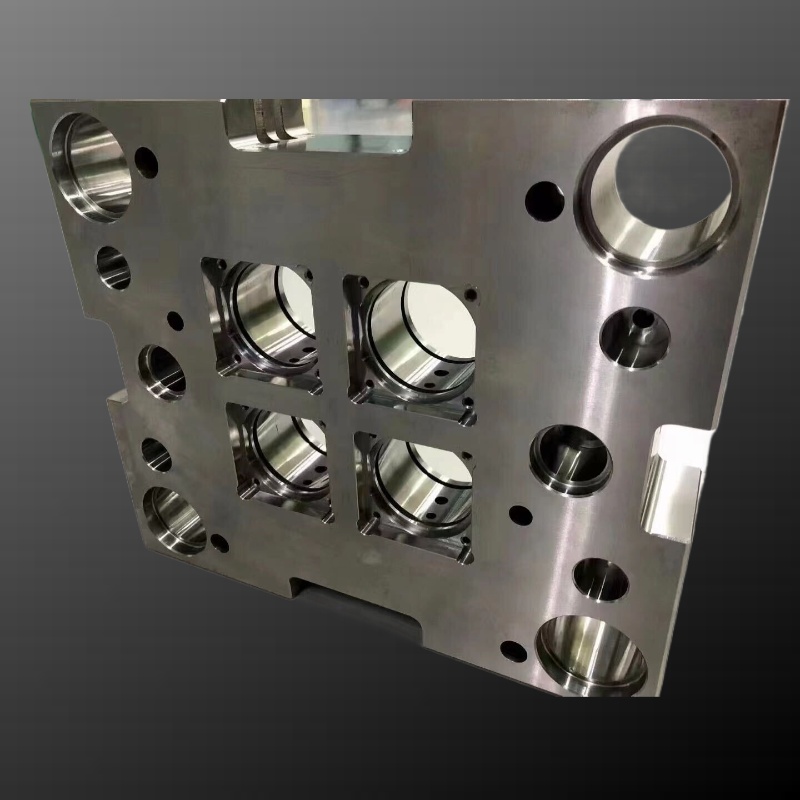

Professional Production of Injection Mold Bases

Our injection mold base production process emphasizes precision and efficiency as its main features. For different plastic products, we offer customized design solutions to meet diverse market demands.

1. Customization Services: We provide personalized mold design solutions based on customer product requirements.

2. Technical Advantages: We utilize advanced processing technologies to ensure high precision and low maintenance costs for the mold bases.

3. Environmental and Energy Efficiency: We focus on material recycling and energy saving during production, achieving green manufacturing.

Customer Service and Support

Our professional team is committed not only to providing high-quality products but also to offering comprehensive after-sales services, including technical support and training, to ensure customer peace of mind and satisfaction during use.

Through continuous innovation and strict management, we have established a strong market reputation.

Product Detail